SLOPING OFF...

...the Newsletter of Christchurch and District Model Flying Club for...June 2022

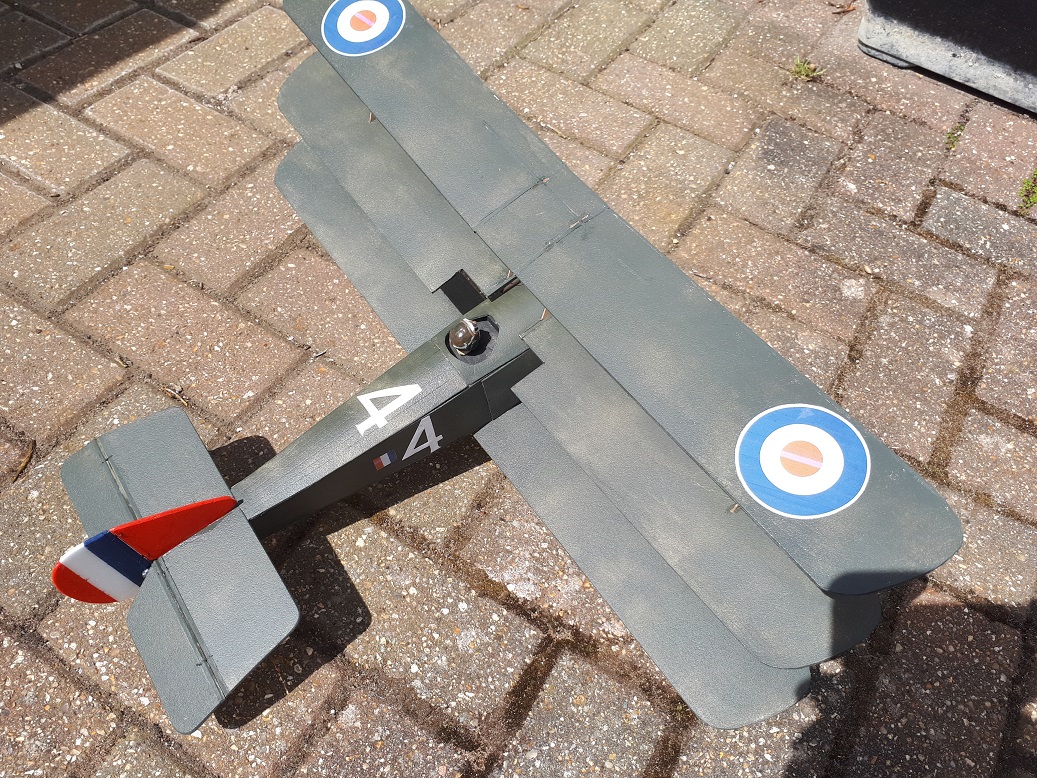

A SOPWITH TRIPLANE FREE PLAN

Egged on by the Fokkers, I decided to make a Sopwith Triplane from B&Q depron-alike, a cheap insulation material but very light and easily worked.

I used my Triplane plan, which is available free from my RC Groups Free Plans thread. I emailed the pdf to Colour Copiers in Highcliffe to be printed at 66%. The original is a 36” span model, so this new one comes out at 24” span. Here’s the original, with a geared speed 400 and 6 NICads at Stanpit one evening years and years ago

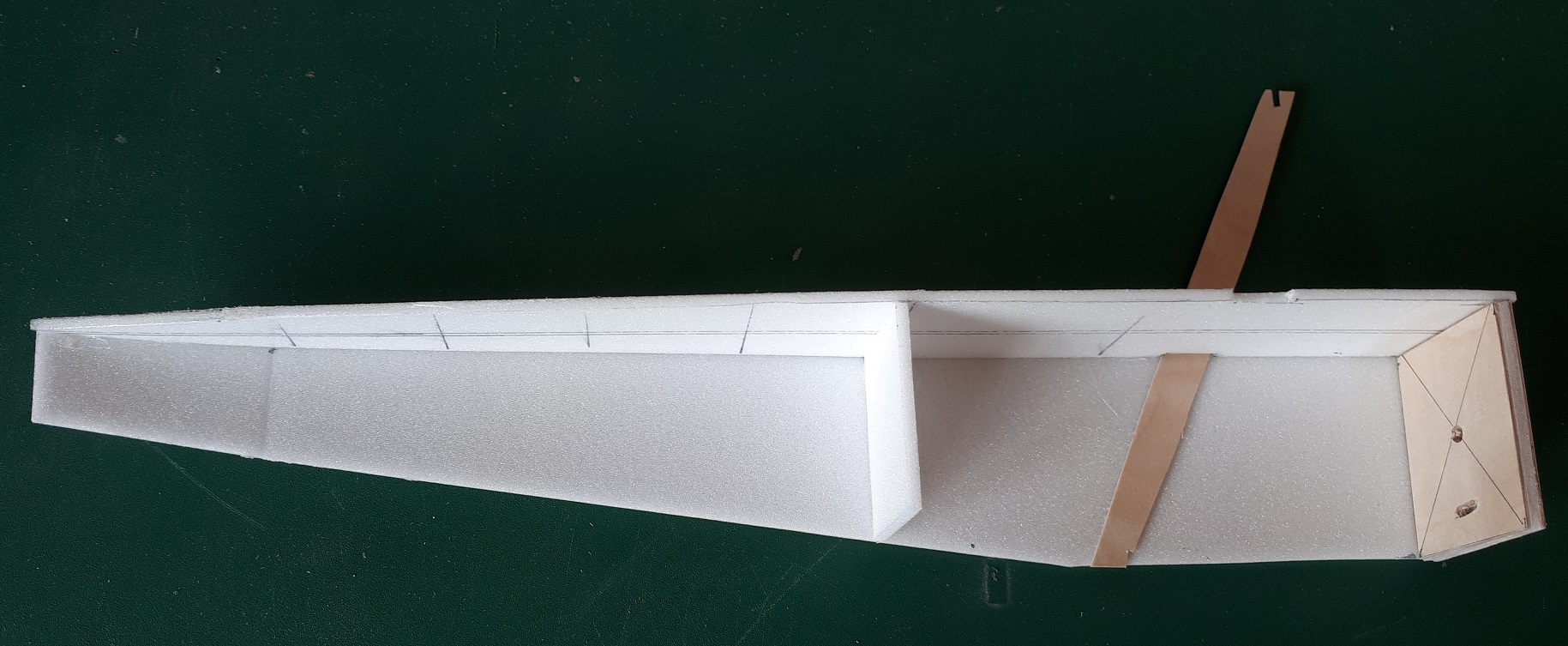

1. Cut out all the parts for the model, allowing 3mm each side where necessary. The plan is accurate, so you should not need to make any changes to the outlines, but you will need to change former sizes to suit . Add 3mm square balsa to the wing LEs, the elevator and tailplane and fin and rudder. These strips strengthen the structure but can be left off if you are going to fly indoors. I made a proper servo tray from thin ply and 3mm depron, but this is overkill. A servo pocket from 6mm depron, each side of the fuselage, one for elevator, one for rudder, would be fine and save weight. The dihedral braces are 2 lams of 0.8 ply and the struts are 0.8 ply, as is the tailskid reinforcement, glued to some depron

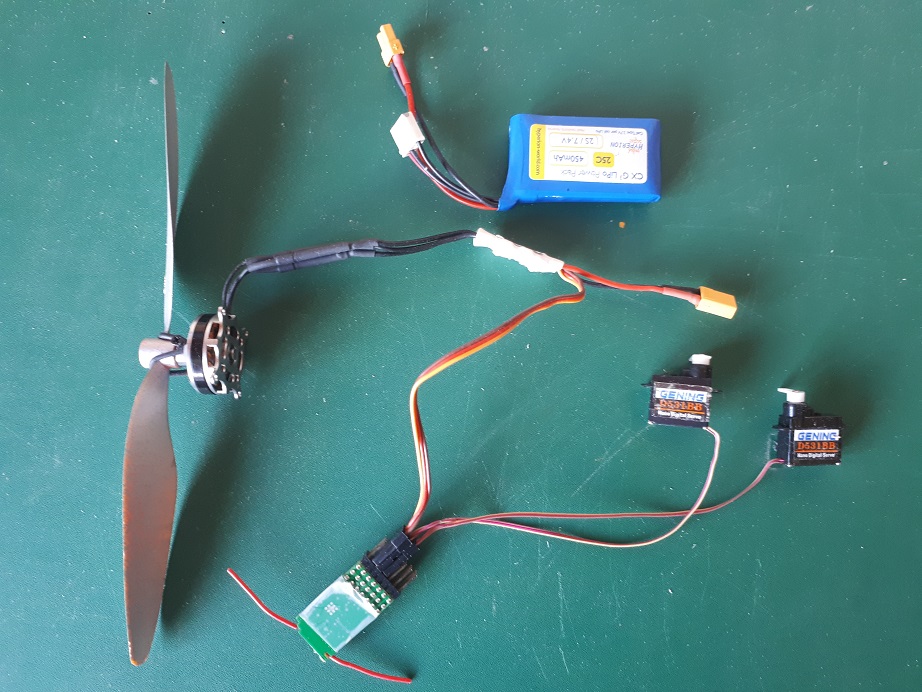

2. The hardware was nicked from other models. The motor and SC came from a shockie at a Club auction some years ago, £5 I recall, the servos from a shameful crash of my Libelle HLG (I now have a new one), the RX from the same and the 2S 450 battery I’ve had for a few years. All this is for outdoor flying. For indoors you could get away with a much smaller and lighter set-up

.

3. Build the fuselage by glueing the inner struts to the sides (one left, one right, remember?) then glue the firewall and a former to the top and the sides to this.

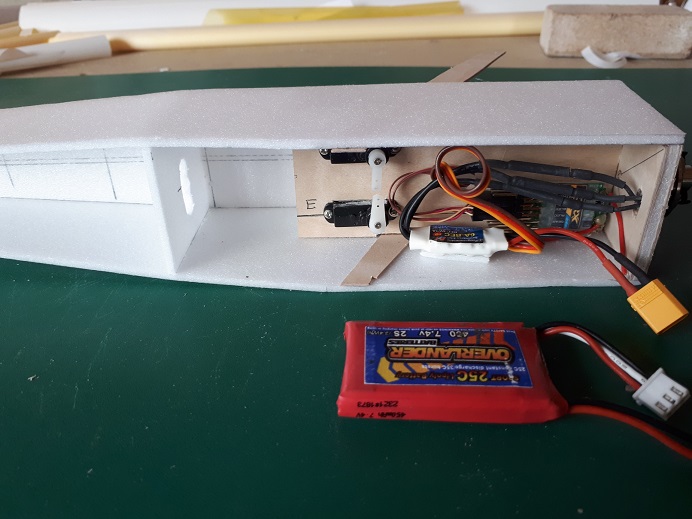

4. You can see that my hardware is grossly large for the model, but the connector is an ST20, so scale effect applies. I used CF rod and paperclips from servos to tail surfaces.

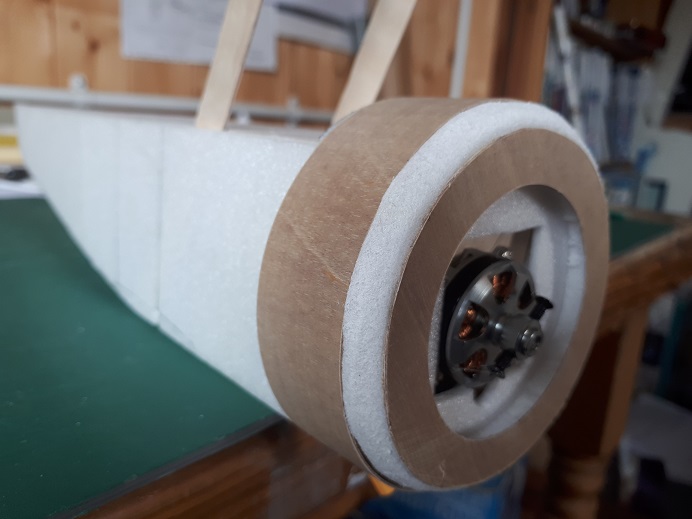

5. The cowl is a wrap of 0.4 ply with another ring of ply to make it a bit stronger.

6. I bent up the UC from the thinnest wire I had and made the wheels from a depron disc with ply reinforcements to hold a piece of tube for the axle to fit in. The UC was sewn to a hardwood strip at the front. This was glued onto the base of the firewall, allowing the UC to swing forward for battery access. Two magnets hold the back of the UC in place.

7. The paint is as near PC10 as Olive Green will allow, the undersurfaces are cream - Irish linen.

8. The markings are drawn up in Word and made into transfers using white-based transfer paper. The figures “4” are from solartrim cut to shape. The Word file is available from me to print at full size for the 24” span model.

So here she is, sort of finished. No Vickers gun, no rib markings, but flyable. She rather disgraced herself on her maiden (all her fault, not mine) when the top wing became detached at the centre section, causing an amusing descent. But after that glue job, she performed well, although needing loads of down trim.As seen, she weighs a portly 6oz, 4oz/sq ft. An indoor version could weight lots less, say 4oz but would need lighter hardware. Anyway, a nice change from the Fokkers, but nowhere near as bombproof!